As a fleet manager operating in the UAE you face a unique mix of challenges: extreme heat, shifting sites and a vehicle mix that ranges from light commercial vans to heavy plant. This guide walks through practical, actionable steps to cut operating costs, keep assets moving and protect your people on site. It’s written for you — busy, results-driven, and keen to see measurable improvements fast.

Throughout the article I’ll reference tools and tactics you can adopt today, and point to deeper resources if you want to explore specific topics. If you’re interested in hands-on support, there’s a simple way to Book demo with Traknova later in the article.

Unique Challenges & Objectives for UAE Construction Fleets

Climate, terrain, and operational environment

The UAE climate is unforgiving. High daytime temperatures, abrasive sand and coastal humidity accelerate wear on cooling systems, air filters and electrical components. On-site conditions — steep access tracks, loose aggregate and frequent loading — increase stress on suspensions, brakes and drivetrains. That means your maintenance cadence should be more aggressive than the OEM baseline. Spend time mapping the most exposed assets and prioritise inspections for cooling systems, tyre condition and air intake filtration. These preventative checks are small investments that avoid lengthy downtime when a vehicle fails mid-project.

Project timelines, site mobility, and asset mix

Construction projects often move quickly between locations or expand across multiple emirates. You’ll be juggling heavy equipment, light commercial vehicles and crew transport all at once. That complexity requires tight scheduling and flexible allocation rules. Consider mobile maintenance units for large sites and plan for rapid redeployment of spares and technicians. Use simple prioritisation rules: keep crew transport and critical support vehicles at highest availability, then backfill less-critical assets. It reduces delays and keeps projects on-time.

KPI priorities for fleet managers

The right KPIs tell you what to focus on. For UAE construction fleets, emphasise availability, cost per operating hour, downtime and fuel efficiency. Track mean time to repair (MTTR) and mean distance between failures (MDBF) for heavy assets, and monitor idling time for site vans. Dashboards that combine utilisation, maintenance history and fuel usage make it easier to act quickly. Set short review cycles (weekly for busy sites) so you spot trends before they become problems.

Vehicle Selection & Procurement Strategies

Choosing the right vehicle types and specs

Picking the correct spec up-front reduces lifecycle headaches. For construction work choose vehicles with reinforced suspensions, higher ground clearance and heavy-duty cooling packages. Specify upgraded air filters and dust-resistant electrical connectors where possible. For vans and pickups, choose payload and load-bed options that match the heaviest regular loads rather than occasional extremes; overspec buys cheaper running costs over time. Standardising on a small range of models helps parts commonality, simplifies driver training and speeds repairs.

Total cost of ownership (TCO) analysis

Don’t let purchase price be the only decision driver. A proper TCO analysis includes depreciation, fuel, maintenance, insurance, downtime risk and resale value. In hot climates the service and cooling bill will be higher; factor that into projected costs. Tools that model different scenarios — intensive site use versus light duty — help justify spending a little more up-front to prevent repeated replacements. For many fleets the lowest TCO option is not the cheapest sticker price.

Leasing vs buying and fleet standardization

Weigh the pros and cons. Leasing can provide predictable monthly costs, easier fleet refresh cycles and access to manufacturer service networks. Buying can be cheaper long-term if you run vehicles hard and keep them well maintained. Either way, standardisation pays: fewer vehicle types mean easier spare-parts management, quicker technician training and quicker diagnostics. If you need help modelling options, our Fleet Insights resource is a good place to start.

Fuel Management & Cost Control

Fuel-efficient driving and route planning

Fuel is one of your largest controllable expenses. Encourage fuel-efficient driving habits with short coaching sessions and clear targets: smoother acceleration, lower idle times and correct tyre pressures. Use route planning to minimise unnecessary site-to-site runs and reduce empty kilometres. On large projects, consider batching trips for deliveries and crew transport to reduce repetitive shuttles. Small reductions in average speed and idling can have outsized impacts on overall fuel spend.

Fuel procurement and bulk purchasing strategies

Negotiate stable pricing with local fuel suppliers and use fuel cards to simplify reconciliation. Bulk purchasing can work if you have secure on-site storage and robust controls. Where possible, centralise procurement for multiple sites to gain scale discounts. Make sure contracts include clear delivery windows and contingency clauses for supply interruptions — you don’t want fuel delays halting a critical crane move.

Monitoring consumption and preventing theft

Fuel loss is often the silent budget killer. Combine telematics with fuel-level sensors to spot anomalies: sudden drops during idle periods, refuelling outside approved locations or mismatches between kilometres and litres consumed. Set up automated alerts and reconciliation workflows so you investigate deviations quickly. If you’re not yet using digital Tracking and sensor integration, it’s worth evaluating — the ROI is usually fast when theft or siphoning are present.

Ready to see these tools in action? Book a personalised demo with Traknova to see how telematics, geofencing and fuel monitoring work on real UAE construction fleets. Click to Book demo and arrange a consultation that maps directly to your projects and KPIs.

Maintenance, Service Intervals & Asset Life Extension

Tailored service schedules for harsh conditions

Standard OEM intervals are a baseline; in the UAE you need to tune them to reality. Heavy dust loads and high ambient temperatures mean more frequent air-filter changes, coolant checks and brake inspections. Create tiered service plans based on duty cycles: light-use crew vans need a different cadence to heavy excavators. Keep a log of failures and adjust intervals if you see repeat issues clustered around certain mileage or hours. Small tweaks now reduce major failures later.

Predictive and preventive maintenance programs

Move from reactive repairs to predictive programmes where possible. Use telematics and fault codes to spot early signs of wear: coolant temperature irregularities, increased idle time or rising fuel consumption. Condition-based alerts allow you to schedule repairs at convenient times, avoiding emergency call-outs and expensive downtime. Predictive approaches also help you plan replacement cycles and budget for major component overhauls.

Parts management and relationships with local workshops

Spare parts availability can make or break turnaround times. Keep a focused inventory of fast-moving items and build preferred relationships with local workshops that understand heavy-duty and construction-specific parts. For specialised components, maintain clear warranty and return protocols. Where possible, use standardised parts across the fleet to reduce SKUs and speed repairs.

Safety, Compliance & Telematics Integration

Regulatory compliance and permits in the UAE

Compliance matters. Different emirates and municipality authorities may require specific permits, vehicle documentation and equipment standards for construction sites. Keep an up-to-date checklist for each project: vehicle permits, insurance certificates, valid driver licences and operator training records. Digital records and audit-ready reports reduce friction during inspections and speed up mobilisation.

On-site safety protocols and driver training

Safety culture starts with simple, repeatable procedures. Enforce site-specific SOPs for vehicle movement, speed limits and reversing protocols. Regular toolbox talks, defensive driving refreshers and clear PPE policies reduce incidents. When an event occurs, an efficient reporting workflow and post-incident review turn lessons into improvements. Training should be short, frequent and focused on the real situations drivers face on your sites.

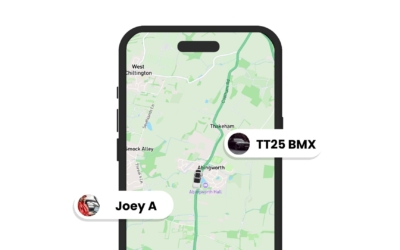

Telematics, tracking and analytics for oversight

A modern construction fleet benefits hugely from integrated telematics. Use GPS Tracking, geofencing, remote diagnostics and dashboards to manage utilisation, enforce site rules and produce automated compliance reports. Telematics also ties into security systems and Dash Cameras for incident verification. When combined, these tools reduce liability, speed investigations and support safer behaviour through data-driven coaching. For practical safety tips for delivery and operational fleets see our piece on Top Safety Protocols.

Conclusion

Optimising UAE construction fleets is about aligning vehicle choice, maintenance, fuel control and safety systems to the specific demands of the environment and project pace. Small, targeted changes — a tighter maintenance schedule, standardised vehicle specs, stronger fuel controls and integrated telematics — compound quickly into lower costs, higher availability and fewer safety incidents. Start with the highest-impact levers for your operation and measure the results. If you want guided support, don’t hesitate to Book demo with Traknova and see these solutions applied to your fleet.

Frequently Asked Questions

How often should I change air filters in the UAE?

There is no one-size-fits-all answer, but in dusty or coastal environments you should inspect air filters at least every 5,000 km or monthly for heavy-use vehicles. Replace proactively if you see pressure drops or increased fuel consumption. Track condition trends and adjust the interval accordingly.

Is leasing better than buying for construction fleets?

Leasing offers predictable costs and easier refresh cycles, which can be attractive if you want to avoid large capital outlays. Buying can be lower cost over long terms if you run vehicles intensively and keep them well maintained. Run a TCO comparison for your usage profile and consider maintenance access and resale markets in the UAE.

What telematics features deliver the fastest ROI?

Start with GPS Tracking, geofencing, fuel monitoring and engine fault alerts. These reduce fuel waste, prevent unauthorised use, speed recovery after theft and allow condition-based maintenance. They typically pay back quickly in reduced downtime and lower fuel costs.

How can I reduce downtime during project peaks?

Prioritise a pool of standby vehicles, pre-stage spare parts at major sites and contract local workshop SLAs for emergency support. Use predictive maintenance data to avoid failures during peak periods and schedule non-critical servicing outside peak windows.

Who do I contact for a system demo or support?

To see how these approaches look in practice, Book demo or Contact us for a consultation tailored to your fleet.