Operating Fleets in Poor Road Conditions: A Manager’s Guide

Introduction

Managing a fleet where the roads are rough, unpredictable or prone to seasonal collapse is a daily challenge. You need to balance safety, uptime and cost while protecting vehicles and drivers from repetitive wear and sudden failures. This guide walks you through practical steps you can take now: how to assess risk, pick the right vehicles and tyres, tighten maintenance, train drivers, and use technology to make smarter decisions. Read on for actionable tips you can implement this week to reduce downtime and keep your operation moving.

Assessing Road Conditions and Operational Risk

Mapping and data collection

Start with a practical information collection plan. Combine official maps, council or road authority reports, and your own GPS traces from past trips. Ask drivers to submit short annotated photos and location-tagged notes after trips. Satellite imagery and elevation maps can show flood plains and washed-out sections that local records may not capture. Stitching these sources together into a single map gives you a clear visual of trouble spots and helps with route planning.

Risk scoring and prioritisation

Create a simple scoring system so everyone evaluates routes the same way. Score by surface type, pothole density, frequency of washouts, bridge or ford quality, and seasonal risk. Weight factors by impact on safety and repair cost. Use the score to allocate tougher vehicles to higher-risk routes and to decide which routes need immediate mitigation or more frequent inspections. A consistent score sheet also makes budgeting and reporting to stakeholders much easier.

Real-time monitoring and alerts

Combine crowdsourced driver reports, telematics feeds and local authority alerts to get near real-time updates. Set up automated alerts for repeat rough-road exposure using accelerometer spikes and suspension fault codes so you can act before failures occur. Have a simple escalation path for drivers to report severe hazards that need immediate attention, and feed those reports back into your risk map to keep it current.

Vehicle Selection and Specification for Poor Roads

Chassis, clearance, and suspension choices

Choose vehicles with higher ground clearance and robust suspension geometry. Light commercial vehicles with reinforced suspensions or light 4×4 options handle rutted tracks far better than low-slung vans. Consider upgrades where appropriate, such as heavy-duty springs or upgraded shock absorbers, to reduce underbody impact and improve ride quality. Remember, a small increase in clearance can save significant repair bills and reduce vehicle downtime.

Tires, wheels and load management

Tires are your first line of defence. Fit tyres with puncture-resistant casings and deeper treads designed for mixed surfaces. Avoid oversized wheels if they reduce sidewall protection; smaller wheels with higher-profile tyres often absorb impacts better. Also implement strict payload controls: overloading increases stress on tyres, suspension and steering, so stick to rated capacities and distribute loads to keep centre of gravity low.

Protective equipment and modifications

Consider underbody guards, skid plates and reinforced bumpers for routes with frequent rocks or debris. Cargo restraint systems reduce shifting loads on rough roads and prevent damage. Where corrosion is an issue, apply protective coatings and ensure drainage points remain clear to avoid long-term structural issues.

Maintenance, Inspections and Spare Strategy

Preventive maintenance scheduling

On poor roads, run higher-frequency maintenance cycles. Increase inspection frequency for suspension bushings, steering components, brakes and driveline U-joints. Make oil and filter checks routine and monitor gearbox and differential wear closely. Use a tiered schedule: basic checks weekly, a deeper inspection monthly, and a full service more frequently than you would on smooth roads.

Pre- and post-trip inspections

Train drivers to do short, consistent pre- and post-trip checks and use a simple checklist that flags common problems quickly. Key checkpoints include tyre condition and pressure, wheel bolts, visible suspension damage, fluid leaks and any unusual noises. Encourage drivers to submit photos with a quick note via mobile to create a traceable record that speeds up repairs.

Parts, spares and repair logistics

Stock critical spares based on historical failure modes: tyres, shock absorbers, brake pads, ball joints and common electrical fuses. Maintain a portable repair kit for field fixes and establish agreements with local garages along high-risk routes. Where supply chains are slow, consider keeping a taxi-sized reserve vehicle pool to cover failures and maintain service levels.

Mid-article CTA

If you want to see how telematics, alerts and route analytics can cut repair bills and downtime, book a demo with Traknova today. Our platform helps you spot rough-road exposure, trigger maintenance and reassign vehicles before failures cost you time and money.

Driver Training, Routing and Operational Protocols

Route planning and pacing strategies

Plan routes that balance distance and road quality. A slightly longer route on a maintained road can cost less overall than a short route that damages vehicles and increases repair frequency. Set realistic ETAs that reflect lower average speeds on rough sections and make punctuality metrics reflect safety and vehicle preservation rather than unrealistic speed. Encourage drivers to adopt a steady pace over aggressive braking and acceleration which increases component wear.

Off-road and hazard avoidance training

Provide hands-on and classroom training in handling potholes, rutted tracks, shallow water crossings and unstable shoulders. Teach drivers how to read the road ahead, pick the best line through a rough patch, and how to decelerate safely to avoid bottoming out. Reinforce safe techniques with periodic refresher sessions and ride-alongs to coach real behaviours.

Emergency response and communications

Have a clear breakdown and emergency protocol. Equip drivers with communication tools that work offline and in low-signal areas, such as satellite-capable phones or messaging apps that cache messages. Define escalation steps, towing procedures, and a protocol for offloading cargo if a vehicle must be recovered. Keep a simple contact card in every vehicle linking to local repair partners and your central operations team.

Technology, Telematics and Cost Management

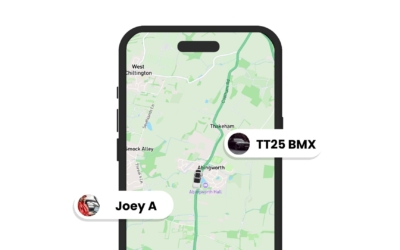

Telematics for condition-aware operations

Install telematics to detect high frequency of bumps, harsh braking, and suspension events so you can quantify rough-road exposure. Use Tracking devices that combine GPS with accelerometers and ride-quality sensors to flag vehicles that need inspection. This moves you from reactive repairs to condition-based actions, letting you allocate resources where they matter most.

Remote diagnostics and predictive maintenance

Use remote diagnostics to read fault codes and monitor component health. Predictive maintenance algorithms can warn you about impending failures so you can plan repairs during low-demand windows rather than reacting to breakdowns. This reduces towing costs and keeps vehicles in service longer.

Budgeting, KPIs and continuous improvement

Expect higher operational expenditure where roads are poor, but measure it accurately. Track KPIs such as cost per kilometre, mean time between failures, downtime and repair frequency. Use these metrics to justify investments in tougher vehicles, improved routing or local repair partnerships. Regularly review your risk map and maintenance data to refine decisions and reduce long-term costs.

Conclusion

Managing a fleet in areas with poor road infrastructure calls for a joined-up approach: solid data, the right vehicle spec, disciplined maintenance, well-trained drivers and supportive technology. Small changes, like better tyres or condition-based servicing, can produce outsized benefits in uptime and total cost of ownership. Start with targeted pilot routes, measure the impact, then scale the interventions that deliver the best return.

FAQs

How often should I inspect vehicles on rough routes?

Increase inspection frequency compared with smooth-road operations. Aim for quick driver pre- and post-trip checks daily, a focused mechanical inspection weekly, and a full service monthly or as driven kilometres and exposure dictate.

Which vehicle upgrades offer the best return?

Tyres with tougher sidewalls, reinforced suspension components and modest increases in ground clearance generally deliver strong returns by reducing punctures and underbody damage. The right upgrades depend on your routes and payloads.

Can telematics really reduce repair costs?

Yes. Telematics that capture ride quality and provide alerts let you act before small issues become big failures. They also help you attribute damage to routes and behaviours so you can prioritise interventions accurately. Learn more about our Fleet Management solutions to see practical examples.

Next steps

If you are ready to reduce downtime and protect your fleet, book a demo with Traknova to see how our tools help with route risk mapping, alerts and maintenance workflows. You can also contact us for a tailored consultation.

We want your feedback

Did you find these tips useful? Please leave a comment, share this article on social media, and tell us what topics you want next. What is the single biggest road-related issue your fleet faces right now?

Enjoyed this guide? If you manage delivery vehicles, you might also like our posts on Digital Logbooks for Loaner Vehicles and Track Kia Hybrids. For safety tech, explore our content on Dash Cameras and fleet Security.